Mailbox:

info@hskcoltd.com

Mailbox:

info@hskcoltd.com

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

China's international medical equipment fair is happening this year, bringing excellent international medical equipment brands to connect with the customers. Hashimoto, being an excellent metal stamping supplier, can benefit medical supplies. China's international medical equipment fair is something you can't afford to miss. In the meantime, this article will tell you how can Hashimoto stamping technology benefit CMEF in 2022.

CMEF 2022 – China International Medical Equipment Fair

CMEF Asia Pacific's medical industry platform serves the whole healthcare value chain through technology innovation, trade, learning, and networking. The China International Medical Equipment Fair (CMEF), which includes exhibitions and seminars, was founded in 1979 and is conducted twice a year, once in the spring and once in the autumn. The CMEF has evolved into one of the world's leading global integrated service platforms in the value chain of medical devices, covering product launches, products and technology, scientific collaboration, procurement and trade, academic forums, brand promotion, education, etc.

Medical imaging, medical examinations, in-vitro diagnostics, and hospital construction are among the products and services offered. In recent years, the CMEF has maintained its growth by introducing over 30 subdivided industrial clusters, including artificial intelligence (AI), magnetic resonance imaging (MRI), computed tomography (CT), operating room, molecular diagnosis, point-of-care testing (POCT), rehabilitation projects, rehabilitation assistive devices, and medical ambulances, all of which present cutting-edge scientific achievements in the medical industry.

What is stamping technology?

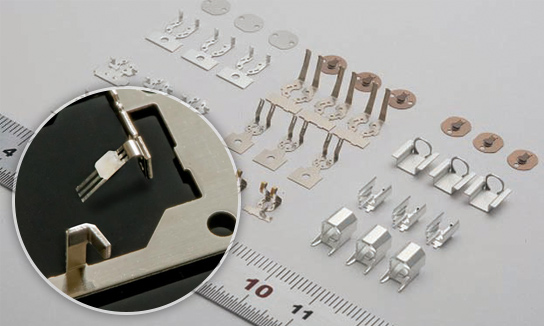

Stamping is a manufacturing technique that uses mechanical stamping technology or ramming to shape sheets or plates of various thicknesses into the desired shape while maintaining the thickness of the original material to the greatest extent. Stamping technologyis frequently utilized in production engineering for three-dimensional components, cutting, or other unique surface needs.

This could be a single-stage operation where every press stroke generates the desired shape on the sheet metal item, or it could be a multi-stage process. The method is most commonly employed on sheet metal, although it can also be applied to other materials like polystyrene. Progressive dies are typically supplied from a steel coil, a coil reel for unwinding the coil, a straightener to level the coil, and then a feeder that feeds the material into the press and dies at a predetermined feed length. The number of stations in the die can be determined based on the part complexity.

How is stamping technology applied in medical instrument hardware?

The medical sector, which includes medical instruments and medical devices, is a multibillion-dollar industry and, in particular, the medical implant industry, is expanding at a breakneck pace. The field continues to grow and evolve as new technologies are developed and offered to the market. When it comes to small and complex parts, it is often overlooked in favor of machining. However, it has seen its share of technological advancements over the years. Metal stampers can now stamp extremely small and intricate shapes to the exact standards required by the medical industry. Metal stamping technology components are already used in a variety of medical devices, tools, and implant components.

Why should you choose Hashimoto as your best stamping supplier?

If you are hesitant to choose Hashimoto as your best stamping technology supplier, let me help you make a wise decision. Hashimoto is known for its excellent items and excellent after-sales services. Pre-sales and after-sales support are provided by the marketing team in a timely and high-quality manner. Respond quickly to quotation requests and offer a complete quotation list (material cost, processing cost, engineering cost, etc.) After-sales tracking service, prompt resolution of various issues, so you may use it with confidence.

The accuracy of metal stamping parts is up to ±0.001 mm, thanks to high-precision testing equipment and a tight production procedure, allowing you to get the best price and the highest quality in the same industry. Hashimoto has adopted scientific work-site management to optimize all production, working hours, quality, and loss links. The punch factory covers a total area of almost 5,000 square meters. To assure high-precision product output, domestic and international production and testing equipment are introduced. We have precision stamping dies with numerous precision punches, WEDM, PG grinding machines, and domestic and foreign inspection and testing equipment to meet the product quality needs of customers. Precision stamping technology components, automation equipment and accessories, precision tooling fixtures, and other products are among the items available.

Basic information about Hashimoto

In December 2002, Hashimoto was founded. Hashimoto's headquarters are in Japan, and in 2012 it purchased land near Hanoi, Vietnam, to build a facility. We handle everything from die design to stamping mass manufacturing, allowing it to respond swiftly to customer demands. Hashimoto has been certified to ISO9001, ISO14001, and IATF16949.

With a camera ND filter and a pet shade, a dust-free room stamping workshop is created. We provide dust-free braided tape packaging or traditional environment braided tape packaging based on product needs. Hashimoto has Japanese heat treatment furnaces, fatigue testing machines and shrapnel loading machines. Our corporate strategy is to strive for market leadership via quality and build a reputation through service. If you have any queries, feel free to contact us.

Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Email: info@hskcoltd.com

Follow us

Copyright ? 2021 Hashimoto Precision Metal (Shenzhen) Ltd

Address: No. 25, Xinfa East Road, Xiangshan Community, Xinqiao street, Bao'an District, Shenzhen 518125, P.R.China

Tel: +86-755-27267875

Mailbox